Pre-concept engineering for the Filtration of Aerosols and Plastic Particles from a Plastic Extrusion Machine (GA12)

ISSUE

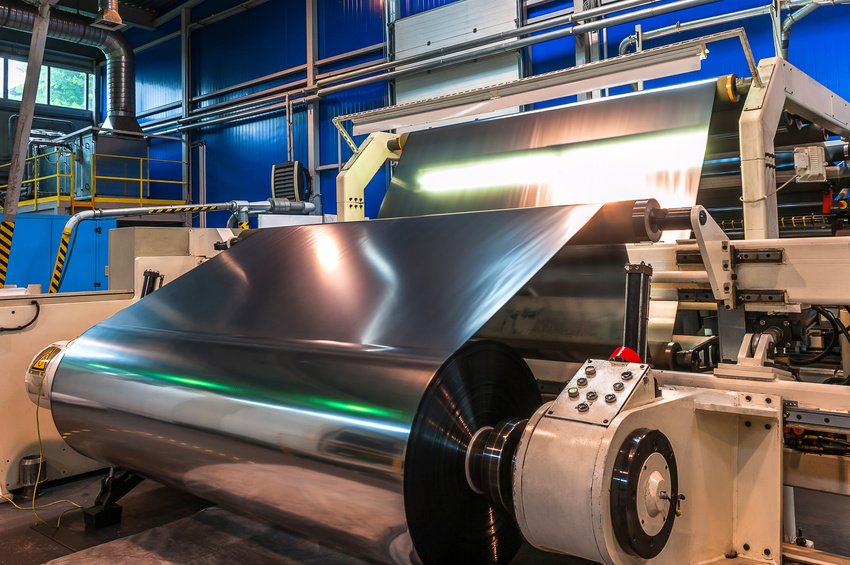

A plastic extrusion and lamination plant is experiencing operating problems with its fume collection and treatment system. During the extrusion and lamination process, plastic particles and aerosols (fumes, oil mist) are generated.

The extrusion machine is equipped with a capture system at the source, but the filtration of the contaminants is not efficient which results in rapid clogging of ventilation ducts and a reduced evacuation of the fumes from the working area.

TECHNOLOGICAL CHALLENGE

STS Canada has been contacted to evaluate the existing ventilation system and to recommend a solution to correct the lack of suction of the system installed on the extrusion line. The objective is to solve the problems of dust collection at the source and to eliminate oil dripping at the discharge stack downstream the system fan.

RECOMMENDED SOLUTION

The mandate was to audit the existing capture system at the source and to make an inventory of the changes that must be made to increase its performance. The study also included the evaluation, selection and sizing of a gas treatment equipment that would capture the sticky plastic particles, fumes and oil droplets present in the gases generated during the extrusion of the plastic film.

RESULTS

First, an audit of the ventilation network showed that it must be modified because the airflow is insufficient to allow adequate capture at the emission points. Also, some components of the ventilation system must be modified to allow the capture system to operate in optimal conditions. The study confirmed that additional filtration equipment is required to prevent the clogging of the duct downstream the system fan due to uncaptured oils, fumes and sticky particles remaining in the gas. The selection and sizing of this filtration equipment was also included in the same study.

EXPERTISE

Gas treatment

Air filtration on media

Industrial ventilation

INDUSTRY

Manufacturing Industry

Plastic Extrusion and Lamination

TASK PERFORMED

Audit

Pre-Concept

Engineering

Study

ESTIMATED COST

14000 CAD $

YEAR

2017