OPTIMISATION OF AN ULTRAFILTRATION UNIT IN AN ALUMINUM CABLE MILL (AA5)

ISSUE

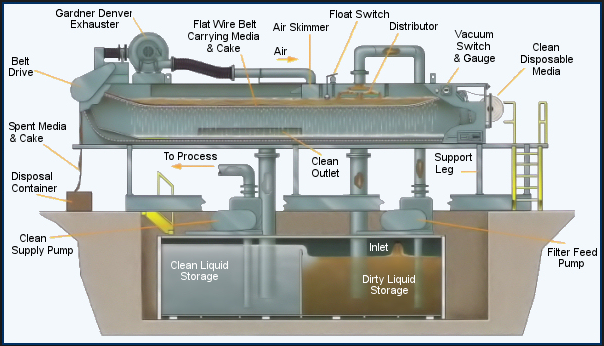

A cable mill located in the province of Quebec uses a belt filter with a polyester spunbond media for its emulsion filtration. When changing the emulsion for a fresh one, the laden emulsion is sent to an ultrafiltration system to filter out as much particles as possible before being sent out to the effluent sector. The ultrafiltration membranes lasted only a few months, which was a lot shorter lifespan than what the work expected. STS Canada was assigned the task to reduce the particle load in the emulsion as much as possible and consequently increase the membranes' useful life.

TECHNOLOGICAL CHALLENGE

This ultrafiltration is sensitive to fouling from solid particles because the membrane's pores are extremely small and easy to clog. Also, the recommended system should handle at least the same flow as the system in place.

RECOMMENDED SOLUTION

STS Canada performed lab testing on belt filter adapted membranes in order to sort out which was best suited for its client. Optimization of the parameters was achieved to reduce the quantity of solid particles in the emulsion all the while maintaining an appropriate flow to the belt filter.

RESULTS

The outcome of the analysis enabled STS Canada to identify the proper fitter media to use. This media allowed the reduction of the particle load by half all while maintaining the same flow as the previous filter media.

EXPERTISE

Liquide processes

Emulsion filtration

Solid liquid separation

Ultrafiltration

INDUSTRY

Mine and Foundry

Metal machining

Aluminum cable rolling mill

TASK PERFORMED

Analytical investigation

Filter media degradation mechanism identification

Filter media selection

ESTIMATED COST

6300$ANNÉE

2008