CONCEPT STUDY AND SIZING OF AN OIL IN WATER SEPARATION EQUIPMENT FOR A BELGIUM COPPER HYDROMETALLURGICAL PLANT (LA32)

ISSUE

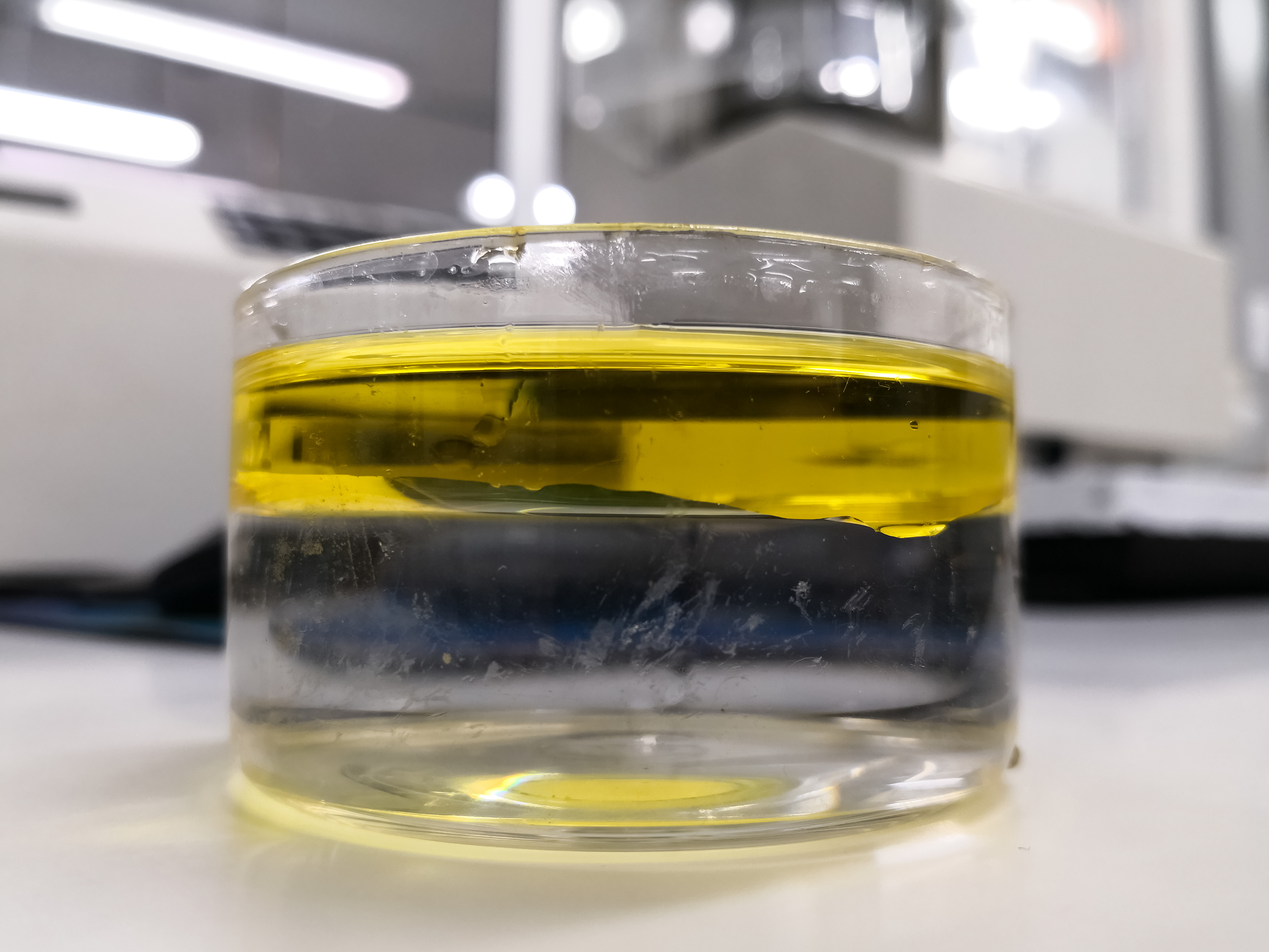

The process to be installed in a copper hydrometallurgical plant in construction in Belgium has been designed by a third-party engineering group. This process is based on a chain of liquid/liquid extraction steps where the copper, in ionic form, is transferred from an organic phase to an aqueous phase (spent electrolyte). The spent electrolyte charged with copper is then electrolysed to recover the copper in his metallic form.

At two points in the process, the third-party engineering group proposed to use hydrocyclones separators to recover the organics contained in the spent electrolyte. The hydrocyclones separators had to lower the organic content in the spent electrolyte from up to 500 ppm v. to less than 20 ppm v.

However, since hydrocyclones separators have been selected on the basis of a distribution curve and indicative performances received from an hydrocyclones supplier, the client, an engineering firm responsible for conception and erecting of the plant, wanted to validate that this technology was indeed the best for this application in terms of reliability, performances and cost.

TECHNOLOGICAL CHALLENGE

STS Canada had to identify, size and evaluate the cost of the most suited separation technology to achieve a content of 20 ppm v or less of organics in the spent electrolyte. The choice of the technology had to take into consideration many criteria including the very acidic characteristic of the spent electrolyte, the restrained footprint available, very tight schedule of the project, the lack of information regarding the shape and size of the oil droplet in the spent electrolyte.

RECOMMENDED SOLUTION

STS Canada first established with the client the list of design criteria. Subsequently, the performances of the different liquid/liquid separation technologies available on the market were assessed in regard to the various forms of oil in aqueous phase by using STS internally developed tools.

The non-compatible technologies were then discarded while the remaining technologies undergone a second assessment step using the various design criteria established previously with the client. Finally, following the sizing of the selected equipment, quotations were requested from various manufacturers available in STS databank in order to identify the most economical technology among the remaining one and the best supplier.

RESULTS

Following the intervention of STS Canada, hydrocyclone separators, initial technology selected for this application, have been abandoned since not efficient enough and too expensive. Instead, fibrous media coalescers were selected among the 17 liquid/liquid separation technologies available on the market since only this technology was matching the various process requirements for a reasonable price.

Furthermore, thanks to STS Canada's supplier databanks, the manufacturer offering the equipment with the best value for money has been identified and presented to the client.

EXPERTISE

Water treatment

INDUSTRY

Mine and Foundry

TASK PERFORMED

Design Engineering

Concept study and sizing

ESTIMATED COST

14000 CAD $

YEAR

2019